Design of Housings and Hermetic enclosures

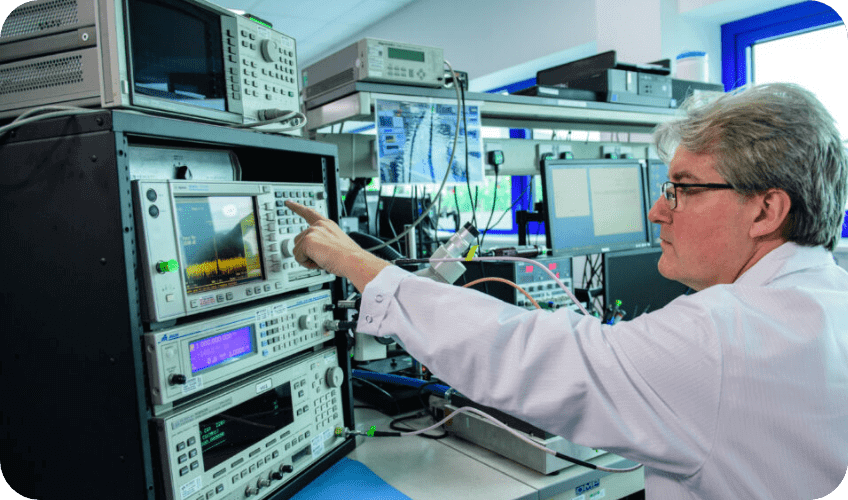

One of the key aspects of custom module design is the choice of environmental protection for the application. Selection of the package or enclosure is the primary consideration for ease of interfacing with the system but also protection to ensure long term service life.

Hermetic sealing is an airtight seal preventing contaminants entering the package. Level of sealing can be selected to prevent, moisture, dust, or other particle ingress.

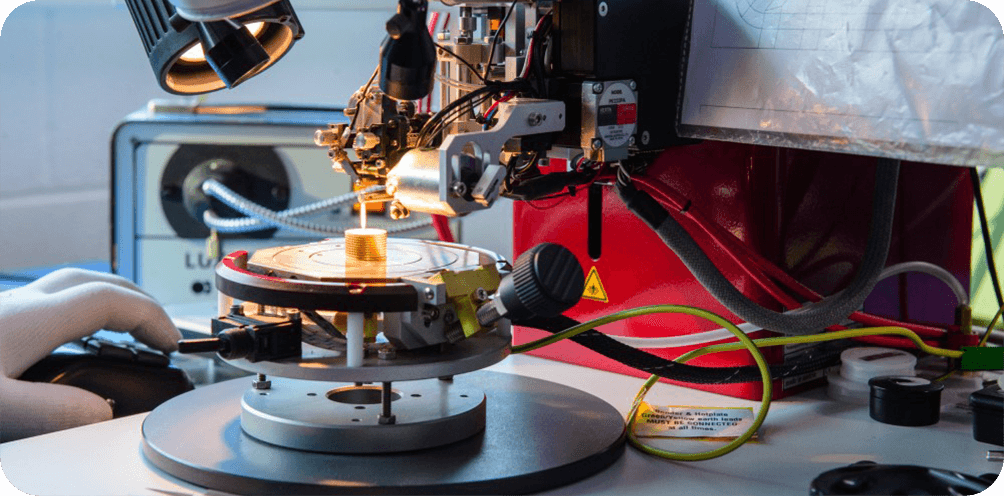

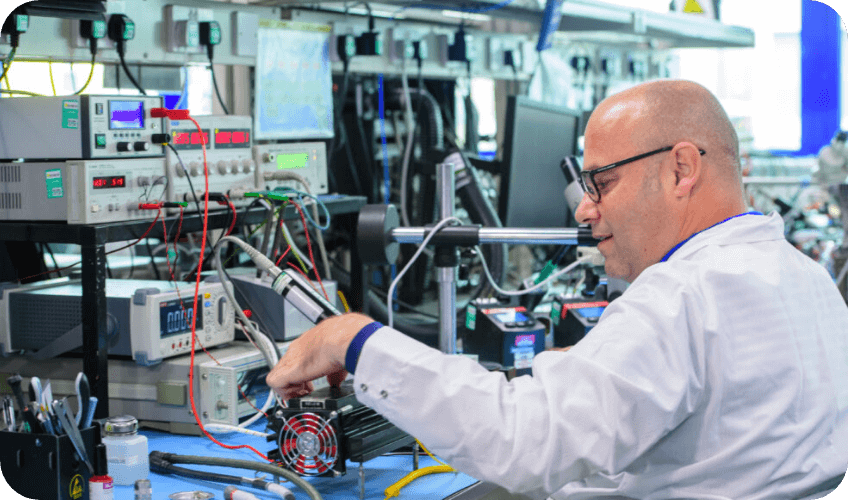

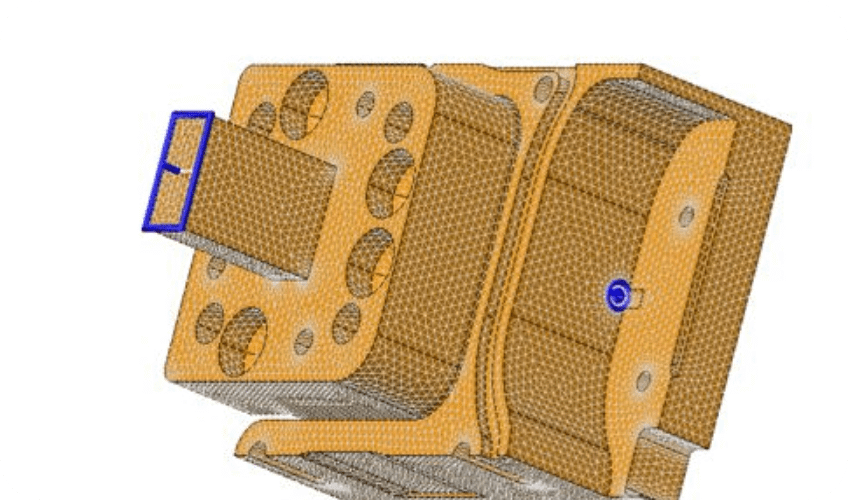

Linwave employ 3D CAD packages to allow solid-model generation and data sharing with stakeholders enabling good system integration and a collaborative design approach with customers. Our standard packages are Altium and Solidworks with output in step format for use in various other third-party tools.

Designs are selected to take account of environmental conditions such as temperature, altitude, vibration, shock, pressure, humidity as well as mandated controls such as hazardous materials, general safety, and EMC/EMI directives. Specific applications such as airborne incur specific standards such as the DO-160 Environmental conditions and test procedures for airborne equipment.

The selection of a custom module allows the user to benefit from the flexibility to modify the shape and size of the product to allow for optimum interfacing, rather than build a system around several set blocks of standard supplier units.

Based on the wide scope of applications we support; our range of packing solutions is considerable; typically selected by collaboration with the system architect on the needs of the application.

About Design of Housings and Hermetic enclosures

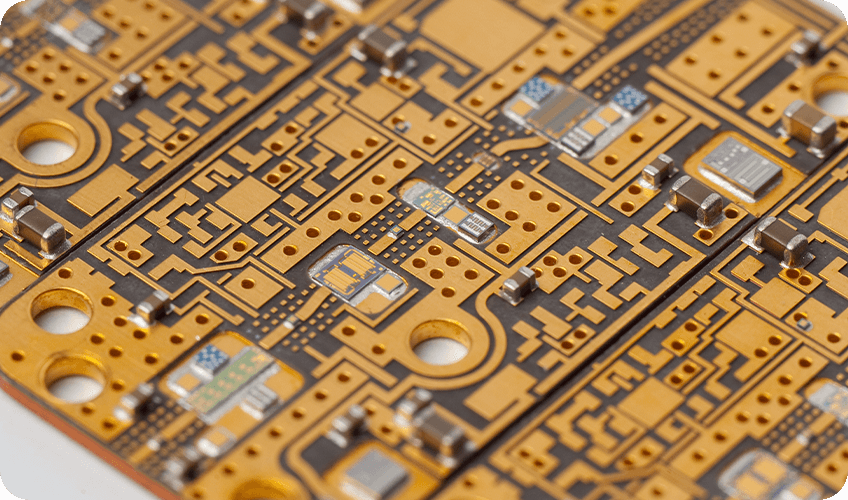

Airborne electronics has seen a migration to VPX interface standard, this allows data intensive interfaces that can run at speeds up to 10Gbit/s. The standard evolved from Vita standards group that have collaborated to deliver PCI card and VMEbus standards. Linwave have adapted their hermetic module enclosures to interface with VPX effectively allowing optimised systems interfacing via backplanes. High vibration environments are covered by Vita 46 key alignment. Coaxial interfaces for microwave frequencies are available thro’ locking SMP or suitable sub miniature connectors. At microwave frequencies we can integrate alternate interfaces such as Waveguide for minimised loss and fibre interface for data capacity.

Defence applications can be supported by Mean Time Between Failure (MTBF) reliability calculations to MIL-HDBK217.

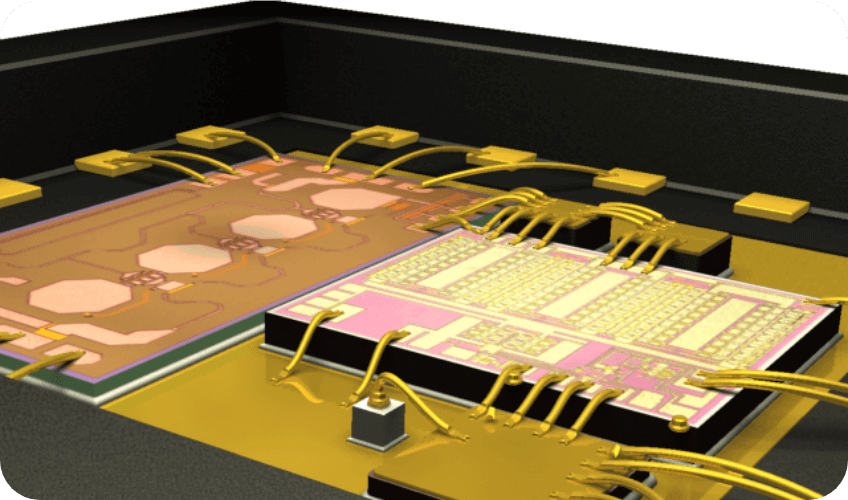

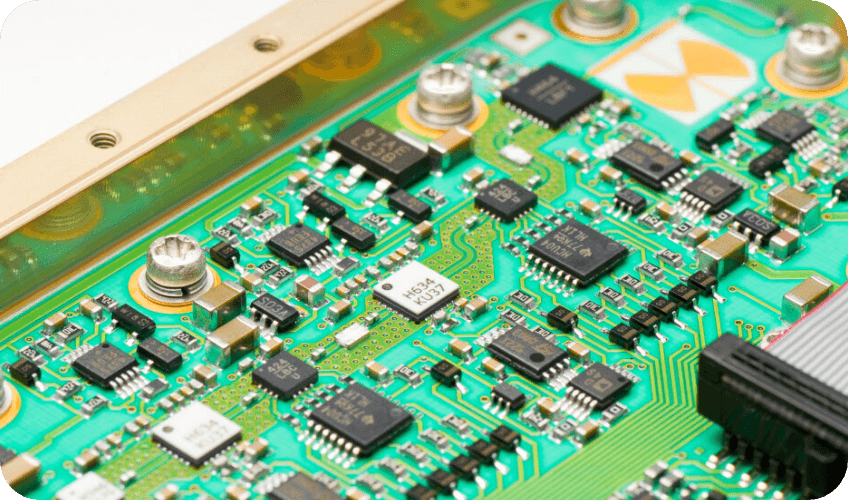

Some examples of die enclosures are QFN and Kovar based.

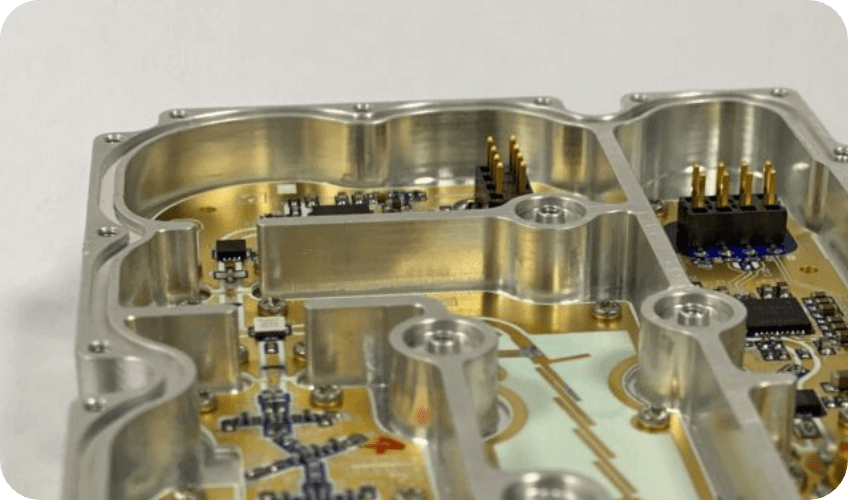

QFN (quad flat no lead) packages allow the mounting of multiple die level components, with associated tuning and biasing in an air cavity package that can be sealed and presented for standard solder mounting. This enables the user to optimise performance, shrink combined size and realise the benefits of simplified handling. Specifications for packaged RF semiconductors are generally stated with wide tolerance or as typical performance as standard, so the user benefits from specific tightening of performance management in their area of concern.

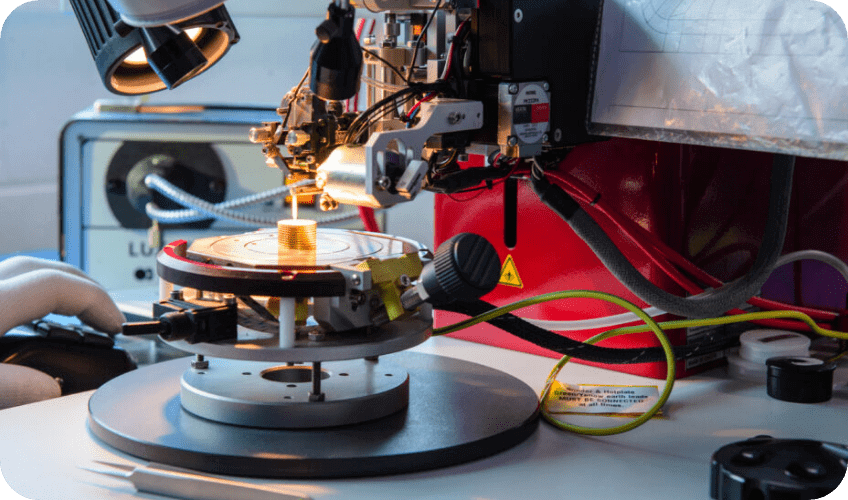

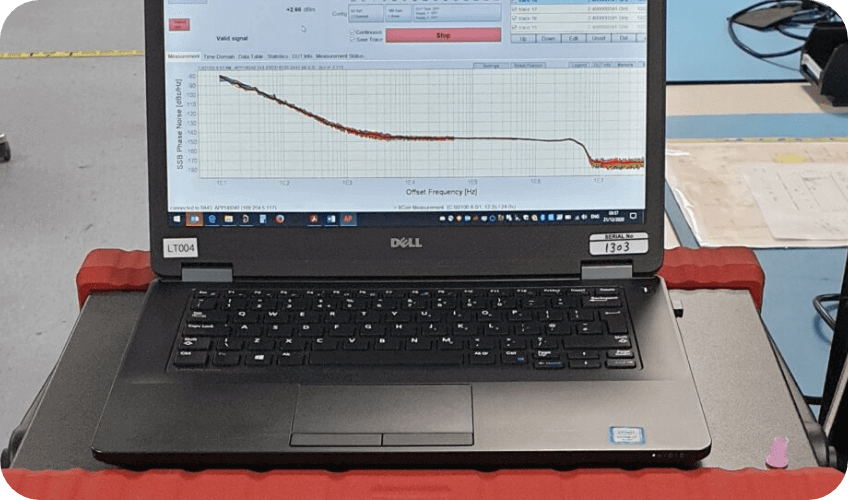

Based on the frequency of application specialized packaging solutions using kovar with laser or compression welded seals can provide coverage of frequencies up to 100 GHz with high specification, low-level leak rates.

For high frequency two terminal devices Linwave specialise in the supply of millimetre wave diodes for waveguide mounting that are sealed in an inert environment. Packages are available to waveguide mount by screw in or press fit methods. These packages offer low parasitic capacitance and good thermal contact, the products are found in high frequency Gunn oscillators utilising high fundamental frequency of operation.

Contact us about our skills